Grease traps are essential not only for operational efficiency but also for complying with health and environmental regulations. Failure to properly manage grease can lead to severe fines and disruptions in business operations. Especially for businesses operating on a budget, knowing how to effectively manage and maintain grease traps is vital to prevent unexpected expenses related to plumbing emergencies.

It’s important to note that grease traps vary in design and application, adapting to different commercial kitchen sizes and needs, from individual sinks to larger facilities, highlighting the diversity in grease trap technology.

How does a commercial grease trap work?

A grease trap is a plumbing device designed to intercept fats, oils, and greases (FOG) from wastewater before they enter sewage systems. This prevents clogging and potential damage to plumbing infrastructure, which can be costly to repair. Grease traps play a pivotal role in helping to prevent grease from passing into the sewer system, ensuring that FOG and other solids do not clog or erode pipes and drains.

For cost-conscious businesses, understanding the mechanics of grease traps helps in making informed decisions on maintenance schedules and potential upgrades that balance effectiveness with affordability. Maintaining these systems shouldn’t break the bank, and with the right knowledge, you can ensure they operate efficiently without overspending.

Table of Contents

What is a Commercial Grease Trap?

Definition

A commercial grease trap is a plumbing device designed to intercept most greases and solids before they enter a wastewater disposal system. Commonly used in commercial kitchens, a grease trap is essential for trapping fats, oils, and greases (FOG), collectively known as FOG, from cooking and cleaning processes.

Purpose

The primary purpose of a grease trap is to prevent FOG from entering and clogging municipal sewer systems. These substances can solidify and cause significant blockages in sewage pipes, leading to expensive repairs and environmental damage. By capturing these materials, grease traps play a crucial role in maintaining the efficiency of both onsite and public wastewater treatment facilities.

Historical Context

The concept of grease traps has been around since the Victorian era, originally developed to prevent animal fats from clogging sewer systems as cities grew and sanitation needs evolved. Modern grease traps, while more advanced, still function on the same basic principle: using a containment system to separate FOG from water by allowing the grease to float to the top due to its lower density compared to water.

This simple yet effective mechanism has made grease traps an indispensable part of restaurant and food service sanitation, helping facilities comply with local grease management regulations and avoid penalties associated with sewer blockages.

Understanding how does a commercial grease trap work is fundamental for any business involved in food service. Properly maintained grease traps not only support compliance with health and environmental regulations but also contribute to the operational efficiency and sustainability of the business.

How Does a Commercial Grease Trap Work?

Understanding how does a commercial grease trap work is crucial for maintaining an efficient kitchen and complying with environmental regulations. Let’s break down the functionality, the separation process, and how these systems manage fats, oils, and greases (FOG).

In this context, it’s important to compare automatic grease traps and manual grease traps. Automatic grease traps are praised for their efficiency, sustainability, and cost-effectiveness over a three-year period compared to manual grease traps. Manual grease traps, on the other hand, are traditional systems that are often used in smaller establishments due to their lower initial investment cost and the availability of various sizes.

Additionally, when discussing gravity grease traps, it’s essential to mention grease interceptors as a critical type of grease management system. Grease interceptors are designed to prevent fats, oils, and grease from entering the drainage system by providing technical considerations for sizing and functionality, highlighting their importance in commercial kitchens.

Functionality

A commercial grease trap is designed to intercept greases and solids before they enter the wastewater disposal system. This is vital because these substances can solidify and clog pipes, leading to expensive repairs and environmental damage.

Separation Process

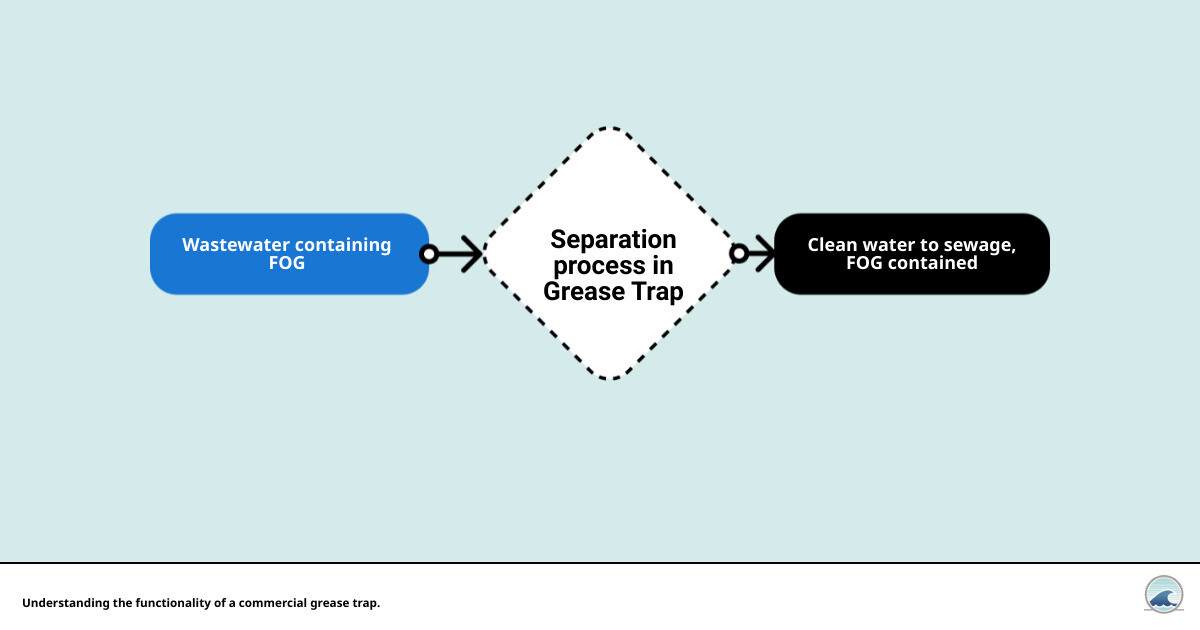

When wastewater enters the grease trap, it goes through a cooling process that helps separate the grease from the water. Grease, being lighter than water, floats to the top. The trap contains this grease while allowing the cleaner water to flow out towards the sewage system.

FOG Management

Proper FOG management within a grease trap involves routine cleaning and maintenance to ensure that the accumulated grease doesn’t overflow or escape into the sewage system. This process is essential to prevent blockages and maintain the efficiency of the wastewater treatment.

Types of Commercial and Automatic Grease Traps

There are several types of grease traps that cater to different needs:

- Passive Grease Traps: These are compact and usually installed indoors, under sinks or near dishwashers. They use natural water flow to separate grease from water.

- Automatic Grease Removal Units (AGRU): These systems automatically separate and remove grease from the water on a set schedule, reducing manual cleaning requirements.

- Gravity Grease Traps: These are large, in-ground tanks that use gravity to separate grease from water. They are suitable for high-volume environments and require periodic pumping.

Components of a Grease Trap

To understand the inner workings, here are the key components of a grease trap:

- Flow rate controller: This part regulates the speed at which wastewater enters the trap, ensuring efficient separation.

- Inlet pipe: Wastewater from the kitchen flows into the grease trap through this pipe.

- Baffles: These are barriers within the trap that slow down the flow of wastewater, allowing grease to rise to the surface and solids to settle at the bottom.

- Water: The addition of water helps to cool down the wastewater, which assists in the separation process.

- Outlet pipe: After the grease is separated and contained, the cleaner water exits the grease trap through this pipe and moves on to the sewer system.

Each component plays a crucial role in ensuring that the grease trap functions properly and efficiently. Regular maintenance and understanding the operation of these components are essential for preventing clogs and ensuring that your kitchen runs smoothly.

We’ll look into the best practices for installing and maintaining these systems to maximize their efficiency and lifespan. This includes choosing the right location for installation and understanding the frequency and methods of cleaning required to keep your system in top condition.

Installation and Placement of Commercial Grease Traps

Choosing the right location for the installation of a commercial grease trap is critical for its efficiency and ease of maintenance. Here we’ll explore the best practices for placement, whether it’s under the sink, in-floor, or outdoors. It’s essential to ensure the grease trap is properly connected to the kitchen’s drain or waste pipe, as this connection is crucial for intercepting FOG (fats, oils, and greases) and containing food waste, thereby enhancing the functionality of the sewer system.

Location Guidelines

When deciding where to install a grease trap, consider accessibility for cleaning and maintenance, the proximity to kitchen waste sources, and compliance with local regulations. The installation spot should allow for easy access to the trap for regular inspections and pumping without disrupting kitchen operations.

Under Sink Installation

Under sink grease traps are common in smaller kitchens or where space is limited. These traps are compact and connect directly to the plumbing from sinks and dishwashers. When installing under the sink, ensure there is enough room to remove and service the trap. This placement is ideal for low to moderate grease volumes.

In-Floor Installation

For larger kitchens with higher volumes of grease, an in-floor installation might be more appropriate. These units are installed below the kitchen floor, offering larger capacity and less frequent cleaning cycles compared to under sink models. In-floor grease traps require careful planning to ensure they do not interfere with kitchen operations or pose a safety hazard.

Outdoor Placement

Outdoor installations are suitable for very large grease traps or interceptors. These are typically used by high-volume food establishments and are buried underground. The key advantage is their large capacity, which minimizes the frequency of cleanings. However, they must be protected against extreme weather conditions and should be easily accessible for maintenance vehicles.

Considerations for All Installations

Regardless of the installation type, there are several factors to keep in mind:

- Proximity to Food Waste Sources: The closer the grease trap is to the source of the grease, the more effective it will be.

- Compliance with Health and Safety Standards: Ensure that the installation complies with local health and safety regulations to avoid penalties.

- Ease of Access: Regular maintenance is crucial, so install the grease trap in a location where service personnel can easily access it.

By following these guidelines, you can ensure that your grease trap is not only effective at trapping fats, oils, and grease but also convenient to maintain and compliant with local regulations. Proper installation is the first step toward a hassle-free grease management system in any commercial kitchen.

Maintenance and Cleaning of Commercial Grease Traps

Maintaining and cleaning commercial grease traps, especially the restaurant grease trap, is essential to prevent clogs, odors, and potential backups that could affect your business operations.

The restaurant grease trap plays a pivotal role in preventing FOG (fats, oils, and grease), sugar, and other solids from entering the sewer system. Ensuring you have a functioning grease trap is crucial to prevent clogs and ensure efficiency in managing restaurant grease and complying with FOG regulations. Regular professional cleaning based on the grease trap’s size, flow, and use is important to maintain its efficiency and comply with city ordinances.

Here’s what you need to know to keep your grease trap functioning efficiently.

Additionally, it’s important to properly dispose of cooking oil to prevent damage to the grease trap and plumbing systems, which helps in preventing sanitary sewer overflows and managing restaurant grease effectively.

Preventing Grease Trap Clogs

Best Practices:

- Avoid pouring grease directly down the drain. Even small amounts can accumulate over time, leading to significant blockages.

- Scrape dishes thoroughly before washing. This minimizes the amount of food waste that enters the trap.

- Use strainers in sink drains. These catch larger pieces of food and debris that could clog the system.

Employee Training:

Ensure all kitchen staff are trained on the importance of grease trap maintenance and the correct disposal methods for fats, oils, and grease. Regular reminders and posted guidelines can help reinforce these practices.

Proper Waste Disposal:

Educate your team on how to dispose of grease and oil correctly. Rather than pouring it down the drain, it should be collected in a designated receptacle and either recycled or disposed of according to local regulations.

Signs of Grease Trap Issues

Odors:

A well-maintained grease trap should not emit unpleasant smells. If you notice foul odors around your grease trap area, it’s a sign that it needs cleaning.

Slow Drainage:

If sinks start draining slower than usual, this could indicate that the grease trap is reaching capacity and needs to be cleaned to ensure continued efficient operation.

Visible FOG:

Visible fats, oils, and grease in the vicinity of the drain or on the surface of standing water in the sink can be a clear indicator that the grease trap is not functioning properly.

Cleaning Frequency and Methods

Professional Services:

Hiring a professional service like Blackstone Septic Service ensures that your grease trap is cleaned thoroughly and responsibly. Professionals can also inspect for any potential issues that might not be visible to the untrained eye.

DIY Tips:

For smaller or less frequently used traps, DIY cleaning might be an option. This includes:

- Regularly removing and cleaning the baffles and screens.

- Flushing out the system with water to remove any lingering grease.

However, for most commercial settings, professional cleaning is recommended to meet health and safety standards and to ensure the longevity of your plumbing systems.

By understanding and implementing these maintenance and cleaning practices, you can ensure that your commercial grease trap works effectively, preventing costly and unsanitary backups and maintaining a clean and efficient kitchen environment.

Cost-Effective Grease Trap Solutions

Managing fats, oils, and grease (FOG) in a commercial kitchen can be challenging and costly. However, innovative solutions like BioCeptor systems and GreasePak biofluid offer cost-effective and efficient ways to handle waste. Let’s explore these options along with other alternative technologies that can help keep your grease management system running smoothly without breaking the bank.

BioCeptor System

The BioCeptor system combines grease trapping and biological treatment. This system not only captures FOG but also uses bioremediation to break down the grease. The presence of specialized biofluids enhances the breakdown process, extending the maintenance intervals. In practice, the BioCeptor can extend the cleaning frequency from the standard 28 days up to 12 weeks, significantly reducing maintenance costs.

Benefits of BioCeptor:

- Extended cleaning intervals: Reduces the frequency of professional cleanings required.

- Effective FOG management: Ensures compliance with health and environmental regulations.

- Cost savings: Lower maintenance and cleaning costs over time.

GreasePak Biofluid

GreasePak biofluid is another innovative solution that offers an effective way to manage grease in commercial kitchens. This biofluid contains enzymes that specifically target and break down fats, oils, and grease in the wastewater. When used in conjunction with mechanical grease traps, GreasePak can enhance the efficiency of FOG breakdown, leading to fewer blockages and reduced odors.

Advantages of GreasePak Biofluid:

- Highly effective: Breaks down FOG at a molecular level.

- Environmentally friendly: Uses natural enzymes that are safe for wastewater systems.

- Easy to use: Simply added to existing systems without needing significant modifications.

Alternative Technologies

Beyond traditional grease traps and innovative bio-solutions, other technologies can help manage kitchen waste effectively. Here are a few alternatives:

- Automatic Grease Removal Units (AGRU): These systems automatically skim accumulated grease from the water surface inside the trap and deposit it into a collection container. This automation reduces the labor and frequency of manual cleanings.

- Dry Bio-Solids Systems: These systems use absorbents to capture and solidify grease, which can then be disposed of as solid waste. This method is beneficial for kitchens producing high volumes of grease.

- Recycling Programs: Implementing a grease recycling program can not only help with grease management but also turn kitchen waste into a resource, such as biofuel.

Choosing the Right Solution:

Selecting the right grease management solution depends on several factors including the size of your kitchen, the volume of meals prepared, and your budget. Combining mechanical trapping with biological treatments like BioCeptor and GreasePak can provide a comprehensive solution that minimizes maintenance requirements and keeps costs low.

By integrating these cost-effective grease trap solutions, commercial kitchens can maintain high hygiene standards, comply with regulations, and manage operational costs effectively. Always consider your specific needs and consult with a professional like Blackstone Septic Service to determine the best setup for your kitchen.

Effective grease management goes beyond installation—it requires consistent monitoring and maintenance to ensure optimal performance and compliance.

Conclusion

Understanding how does a commercial grease trap work and ensuring its proper maintenance is not just about keeping your operations smooth—it’s also about compliance and environmental responsibility. Every restaurant and commercial kitchen has a duty to prevent fats, oils, and grease (FOG) from entering the public sewer systems. This not only helps in avoiding blockages and potential fines but also contributes to a healthier environment.

Regular cleaning and maintenance of your grease trap are essential. It’s not just about meeting legal requirements—it’s about taking proactive steps to ensure your business operates without interruptions and protects the environment. With Blackstone Septic Service, you can trust that your grease management needs are in good hands, allowing you to focus on what you do best—running your kitchen and serving your customers.

Contact us today at Blackstone Septic Service. We recognize the critical role that grease traps play in your daily operations. That’s why we’re committed to offering comprehensive grease trap cleaning services that ensure your systems are not only clean but fully compliant with all local regulations. Our experienced team uses the latest techniques and equipment to manage your grease traps efficiently, helping you avoid costly downtime and ensuring your kitchen runs smoothly.

Choose Blackstone Septic Service for a cleaner, more compliant kitchen. Let us help you keep your operations slick and smooth, so you never have to worry about grease trap issues again.

Frequently Asked Questions about Commercial Grease Traps

How often should a grease trap be cleaned?

The frequency of cleaning a commercial grease trap varies, but a good rule of thumb is every 1 to 3 months. This guideline helps prevent the buildup of fats, oils, and greases (FOG), which can lead to clogs and inefficiencies. Specifically, it’s recommended to clean the trap when it’s about 25% full of FOG to maintain optimal functionality.

What is the 25% rule for grease traps?

The 25% rule is a maintenance guideline suggesting that a grease trap should be cleaned when FOG and solid waste occupy approximately one-quarter of the grease trap’s capacity. This rule is crucial because once FOG exceeds this limit, the efficiency of the grease trap decreases, and the risk of fats, oils, and greases escaping into the sewer system increases. Regular monitoring and adherence to this rule can help avoid costly fines and plumbing issues.

Can a grease trap handle all kitchen waste?

No, a grease trap is not designed to handle all types of kitchen waste. Its primary function is to intercept and trap FOG before these substances enter the wastewater system. Solid food particles, debris, and non-biodegradable materials should not be sent down the drain as they can cause clogs and damage the grease trap.

Our Content

Our experienced septic tank specialists have carefully reviewed and edited all of the content to ensure that it meets our high standards for quality and accuracy. At Blackstone Septic Service, our mission is to provide unparalleled expertise and service excellence in the realm of septic system care. With a dedicated team of professionals committed to delivering top-tier septic systems and solutions, we specialize in comprehensive services such as routine maintenance of clogged drains, grease trap cleaning, septic tank pumping, septic cleaning, and even new septic system installations. Blackstone Septic Service is a family-owned company with highly trained technicians, with over 75 years of experience in septic tanks.