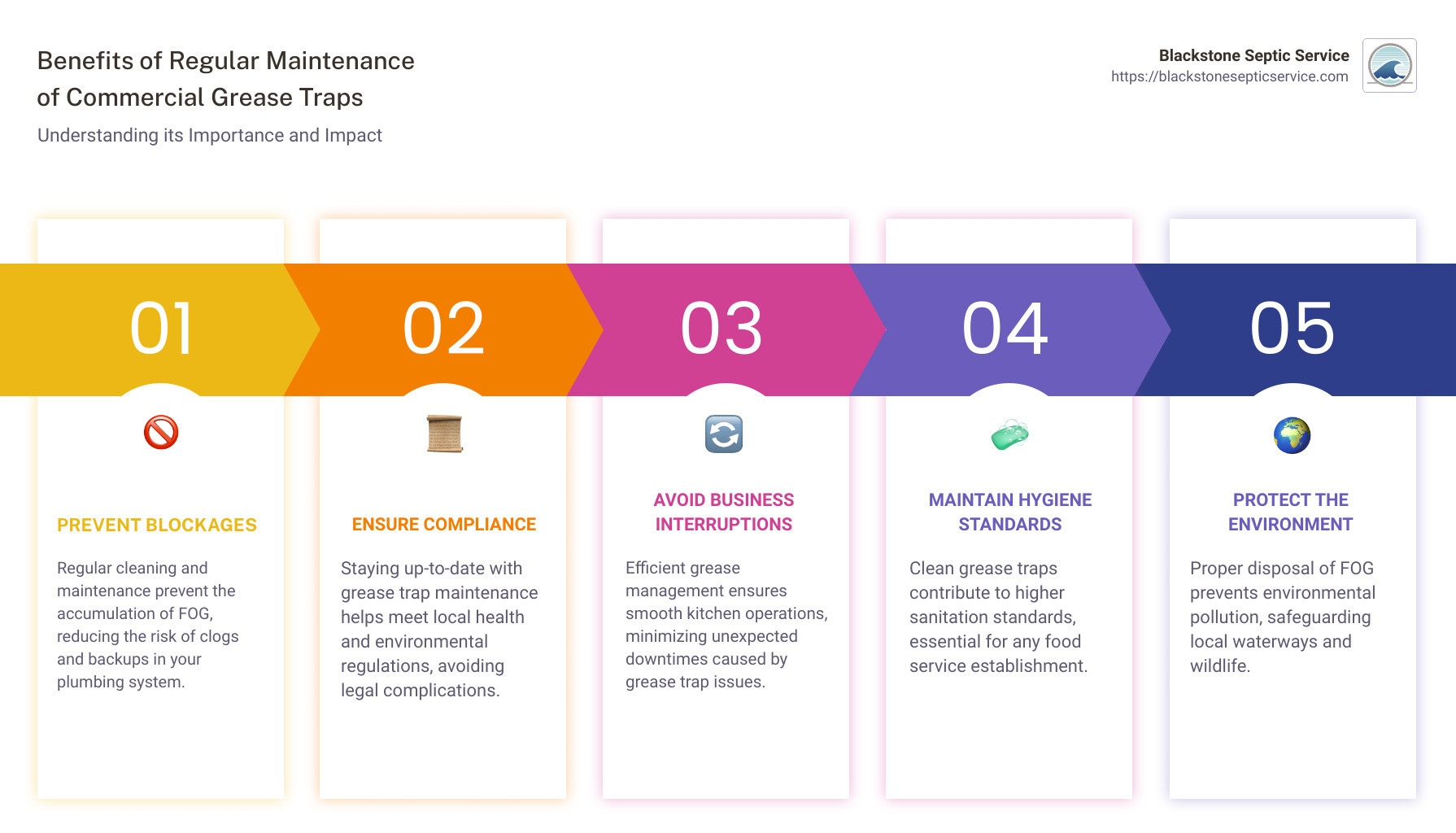

Commercial grease trap maintenance is crucial for any food service business to operate smoothly and comply with local health and environmental regulations. Ensuring that your grease trap is functioning efficiently and keeping grease traps clean can prevent costly plumbing issues, avoid negative impacts on your business operations, local sewer systems, and maintain high sanitation and environmental standards.

Grease traps play a vital role in intercepting fats, oils, and greases (FOG) from wastewater before they enter the sewer lines. If not properly managed, FOG can solidify and cause blockages, leading to overflows, sewage back-up, unexpected expenses, and possible damage. Moreover, maintaining compliance with municipal guidelines is not just a legal requirement but a responsibility towards community health and environmental safety. Regular maintenance ensures your grease trap works effectively, minimizing the risk of unpleasant odors and potential shutdowns due to non-compliance.

Efficiently managed grease traps contribute to smoother kitchen operations, higher sanitation standards, and a lower risk of environmental pollution. Here, we will delve into the importance of maintaining your commercial grease traps and ensuring your practices align with legal and environmental expectations.

Table of Contents

Understanding Grease Traps

Types of Grease Traps

Grease traps are essential devices in commercial kitchens, designed to intercept fats, oils, and grease (FOG) before they enter the wastewater system. Understanding the different types of grease traps can help you choose the right one for your business needs:

- Manual Grease Traps: These are also known as passive traps. They require regular manual cleaning to remove the accumulated grease. They are cost-effective and suitable for smaller establishments.

- Automatic Grease Traps: These traps automatically remove the grease from the water. Known for their convenience, they use a mechanical system to skim the FOG from the top of the trap into a separate container, which is then easily disposed of.

- Gravity Grease Traps: Larger and typically installed underground, these traps use gravity to separate grease from wastewater. They are ideal for high-volume environments but require periodic pumping by professionals.

How Grease Traps Work

The principle behind grease traps is straightforward yet highly effective. Here’s how they manage to keep FOG from clogging the sewer systems:

- FOG Separation: As wastewater enters the grease trap, the fats, oils, and grease, which are lighter than water, begin to rise to the surface. This process is facilitated by the reduced flow rate in the trap, which prevents the FOG from mixing back into the water.

- Wastewater Flow: The design of the grease trap includes a system of baffles or barriers that slow down the incoming wastewater. This slowdown gives the grease more time to separate and rise to the top.

- Cooling Process: As the wastewater cools while it’s in the trap, the grease and oils solidify, making them easier to skim off and remove during maintenance.

Installation Considerations

Proper installation is critical to the effective operation of a grease trap. Here are some key considerations:

- Location: Grease traps should be installed close to the source of the grease, such as near kitchen sinks or dishwashers. This proximity minimizes the chance of grease solidifying in the pipes before it reaches the trap.

- Size and Capacity: The size of the grease trap should be appropriate for the volume of wastewater your facility produces. A trap that’s too small will require more frequent cleaning and may not effectively prevent grease from entering the sewer system.

- Accessibility for Cleaning: Ensure that the installation location allows for easy access for regular cleaning and maintenance. This accessibility will help in maintaining the efficiency of the trap and compliance with health regulations.

Understanding these aspects of commercial grease trap maintenance can significantly impact the functionality of your kitchen and compliance with local regulations. Properly chosen, installed, and maintained grease traps reduce the risk of costly clogs and fines, ensuring that your kitchen operations run smoothly and sustainably.

Commercial Grease Trap Maintenance Essentials

Maintaining a commercial grease trap is not just about keeping your kitchen running smoothly; it’s about adhering to health and environmental regulations and ensuring that your operations are efficient and odor-free. The grease trap cleaning process is a crucial part of maintenance that involves full evacuation and cleansing of the trap, essential for its efficiency. Grease trap pumping is vital for preventing issues and maintaining community health, highlighting the importance of this service in the maintenance routine. Regular grease trap service is beneficial for commercial kitchens and restaurants, preventing blockages, overflows, unpleasant odors, and potential shutdowns, and ensuring the cleanliness and efficiency of the traps. Let’s dive into the essentials of maintaining your grease trap effectively.

Regular Inspection and Monitoring

Safety Checks: Regular safety checks are critical to ensure that your grease trap is functioning correctly and safely. This involves checking for leaks, ensuring that all fittings and seals are intact, and that there is no risk of overflow or blockage.

FOG Levels: Monitoring the levels of fats, oils, and grease (FOG) is essential. The accumulation of FOG should not exceed 25% of the grease trap’s capacity, as this can hinder its efficiency and lead to potential blockages.

Compliance: Regular inspections ensure compliance with local health and safety regulations. Keeping a log of these inspections can provide proof of compliance during health inspections or environmental audits.

Determining Cleaning Frequency

Usage Level: The amount of grease your kitchen disposes of plays a significant role in how often you should clean your grease trap. High-volume kitchens may require more frequent cleanings.

1/4 Rule: As a general guideline, your grease trap should be cleaned when the FOG levels reach about 25% of the trap’s capacity. This is crucial to prevent clogs and maintain efficiency.

Local Regulations: Always be aware of and comply with local regulations regarding grease trap maintenance. Different municipalities may have specific requirements for how often grease traps need to be cleaned and how the waste should be disposed of.

Professional Services

While smaller or less frequently used grease traps might be manageable in-house, for most commercial operations, enlisting professional grease trap cleaning services is advisable. Professionals have the necessary tools and expertise to thoroughly clean and maintain your grease trap, ensuring compliance with all regulations. They can also handle the proper disposal of grease waste, which is critical for environmental protection.

Regular maintenance by professionals can help prevent emergency overflows and costly repairs, providing peace of mind and allowing you to focus on running your kitchen. By scheduling regular service visits, you can ensure that your grease trap is always in top condition, minimizing the risk of unexpected issues.

In conclusion, regular inspection and monitoring, understanding the appropriate cleaning frequency, and utilizing professional services are essential components of effective commercial grease trap maintenance. These practices not only keep your operations running smoothly but also ensure compliance with local health and environmental regulations, safeguarding your business against fines and closures.

Step-by-Step Guide to Cleaning Your Grease Trap

Maintaining a commercial grease trap is crucial to prevent backups and ensure your kitchen runs smoothly. Here’s a detailed guide on how to clean your grease trap effectively.

Pre-Cleaning Preparation

Before you start the cleaning process, it’s essential to turn off any connected automatic dishwasher and sinks. This prevents the grease trap from filling up during the cleaning process, allowing for a more thorough and efficient cleaning.

Cleaning Process

Begin by removing the grease sludge using a shop vac. This step involves vacuuming out the top layer of grease that floats on the surface. After the grease sludge is removed, use soap, warm water, and a steel pot scrubber to clean the trap thoroughly. This includes scrubbing the lids, sides, baffles, and other parts of the grease trap to ensure it is free from all traces of fats, oils, and greases (FOGs) and any blockages.

Pre-Cleaning Preparation

Before diving into the cleaning process, prepare adequately to ensure safety and efficiency:

- Safety Gear: Equip yourself and your team with the necessary safety gear. This includes rubber gloves, goggles, and coveralls to protect against splashes and strong odors.

- Tool Gathering: Gather all the tools you’ll need for the cleaning process. This includes a crowbar for opening the trap, a scraper, a shop vacuum, and buckets for collecting waste.

- Service Shutdown: Ensure that all kitchen operations that could lead to water flowing into the grease trap are halted. This prevents the addition of water and waste during the cleaning process, which can complicate the task.

Grease Trap Cleaning Process

With preparations in place, follow these steps to clean your grease trap:

- FOG Removal:

- Carefully remove the lid of the grease trap using the crowbar. Be cautious not to damage any seals or gaskets.

- Use a scoop or a small bucket to manually remove the layer of fats, oils, and greases (FOG) from the top of the trap.

- Solid Extraction:

- After removing the FOG, there will likely be solid waste settled at the bottom of the trap. Use the shop vacuum to suction out these solids.

- It’s important to ensure all solids are removed to prevent clogging and inefficiencies in the trap’s operation.

- Scrubbing:

- Once the FOG and solids are removed, use a stiff-bristled brush or a scraper to scrub the sides, lid, and baffles of the grease trap.

- This step helps remove any residual grease clinging to the surfaces.

- Rinsing:

- Rinse the interior of the grease trap with clean water to wash away any loose debris and cleaning residue.

- It’s crucial to perform a thorough rinsing to ensure no cleaning agents or debris are left behind, which could contaminate the wastewater system.

After completing these steps, replace the lid securely and ensure all seals and gaskets are intact to prevent leaks. Dispose of the collected waste according to local regulations, typically by using a licensed waste disposal service.

By following this step-by-step guide, you can effectively clean your commercial grease trap, ensuring it operates efficiently and remains compliant with health and environmental standards. Regular cleaning not only extends the life of your grease trap but also prevents unpleasant odors and potential backups in your kitchen.

Continuing into the next section, we’ll explore advanced maintenance techniques to further enhance the functionality and longevity of your grease trap.

Advanced Maintenance Techniques

Preventing and Addressing Overflows

Overflow in commercial grease traps can result in significant issues, including environmental hazards and operational disruptions. To prevent this, regular maintenance is essential. Here’s how you can keep overflows at bay:

- Regular Inspections: Schedule monthly inspections to check for signs of potential overflows and ensure that the grease trap is not reaching its capacity.

- Immediate Response: If an overflow occurs, act swiftly. Shut down the connected water sources to mitigate the overflow and contact a professional immediately.

- Professional Intervention: Utilize services like line-jetting, which involves using high-pressure water jets to clear out blockages in the plumbing lines that lead from the grease trap to the sewer. This method is highly effective in removing the build-up of Fats, Oils, and Grease (FOG) that could lead to overflows.

The Role of Enzymatic Additives

Enzymatic treatments are an innovative approach to maintaining grease traps, but they come with their own set of benefits and limitations:

- Usage: Enzymatic additives are introduced into the grease trap to break down FOG into smaller, less harmful components that are easier to process.

- Benefits:

- Reduced Odors: These additives can significantly decrease the unpleasant smells often associated with grease traps.

- Improved Efficiency: By breaking down grease buildup, enzymatic additives help maintain a clear flow, enhancing the overall efficiency of the grease trap.

- Limitations:

- Not a Complete Solution: While helpful, enzymatic additives do not eliminate the need for physical cleaning and can sometimes just delay the inevitable need for more intensive maintenance procedures.

- Regulatory Considerations: Not all enzymatic additives are approved for use in all regions. Always check local regulations to ensure compliance.

Incorporating these advanced maintenance techniques into your routine can drastically improve the performance and lifespan of your grease traps. Regular use of line-jetting services and strategic application of enzymatic treatments, when appropriate, can prevent the majority of common issues that lead to system failures and costly repairs.

By understanding and implementing these methods, you ensure that your grease trap continues to function effectively, avoiding disruptions that could affect your business operations. As always, partnering with a professional service like Blackstone Septic Service for regular maintenance checks and emergency interventions is crucial to maintaining system health and compliance.

Commercial Grease Trap Maintenance Challenges and Solutions

Common Maintenance Challenges

Maintaining commercial grease traps can be tricky. Here are some of the most common issues that businesses face:

- Clogs: These are often caused by the accumulation of FOG (fats, oils, and grease) and solid waste. Clogs can disrupt the normal flow of wastewater and lead to backups.

- Overflows: If not cleaned regularly, grease traps can overflow. This not only creates a messy situation but can also lead to health hazards and environmental violations.

- Compliance Issues: Adhering to local regulations is crucial. Non-compliance can result in hefty fines and even business closures.

Professional Solutions and Preventative Measures

To tackle these challenges, consider the following expert solutions and preventative strategies:

- Scheduled Cleaning: Regular cleaning is essential. The frequency should be determined based on the amount of FOG your business produces, but a good rule of thumb is to clean your grease trap when it reaches one-fourth of its capacity. This is known as the 1/4 rule and helps ensure that the system operates efficiently without overflows or clogs.

- Expert Assessments: Regular inspections by professionals like those at Blackstone Septic Service can help identify potential issues before they become serious problems. These assessments can check for damage, ensure that all components are functioning correctly, and verify compliance with local regulations.

- Compliance Strategies: Stay updated on local grease management requirements and ensure your business meets all regulatory standards. Professional services are well-versed in local laws and can help you maintain compliance, thus avoiding fines and operational disruptions.

By implementing these solutions and maintaining a regular maintenance schedule, you can prevent most of the common issues associated with commercial grease trap maintenance. This proactive approach not only saves money in the long run but also ensures that your business operates smoothly and remains compliant with environmental regulations.

Partnering with a reliable service provider like Blackstone Septic Service is key. Their expertise and thorough maintenance programs provide peace of mind and keep your operations running without interruption.

Conclusion

Partnering with Blackstone Septic Service

When it comes to maintaining your commercial grease traps, partnering with a service provider you can trust is crucial. Blackstone Septic Service offers reliability, expertise, and a strong focus on customer satisfaction, making them a preferred choice for businesses serious about their maintenance needs.

Our team of skilled professionals is equipped to handle the complexities of commercial grease trap maintenance. With over 75 years of experience, we understand the nuances of different systems and regulations, ensuring that your grease traps function efficiently and comply with all local and state requirements. Our commitment to service excellence means that we consistently go the extra mile to meet and exceed your expectations.

Explore our comprehensive grease trap cleaning services to see how we can keep your operations smooth and compliant.

The Importance of Professional Maintenance

Maintaining your commercial grease traps isn’t just a regulatory requirement; it’s a critical component of running a successful and responsible business. Here’s why professional maintenance is non-negotiable:

- Efficiency: Regular and professional cleaning prevents blockages and ensures your grease traps work effectively, minimizing the risk of costly downtime or emergency repairs.

- Compliance: With changing environmental regulations, having a knowledgeable partner ensures that your business stays compliant, avoiding fines and legal complications.

- Peace of mind: Knowing that your grease traps are managed by experts provides peace of mind, allowing you to focus on other aspects of your business.

Regular maintenance is an investment in your business’s future. It ensures that your operations are not just compliant, but also efficient, safe, and sustainable. By choosing Blackstone Septic Service, you’re opting for a partner who values the integrity of your operations as much as you do.

Contact us today at Blackstone Septic Service, and we can help you maintain a clean, compliant, and efficient environment. Your satisfaction is our priority, and we’re dedicated to providing solutions that not only meet but exceed your expectations.

In conclusion, the long-term benefits of professional grease trap maintenance with Blackstone Septic Service are clear. From ensuring efficiency and compliance to providing peace of mind, our services are designed to keep your business running smoothly. Partner with us and experience the difference that genuine expertise and dedicated customer service can make.

Our Content

Our experienced septic tank specialists have carefully reviewed and edited all of the content to ensure that it meets our high standards for quality and accuracy. At Blackstone Septic Service, our mission is to provide unparalleled expertise and service excellence in the realm of septic system care. With a dedicated team of professionals committed to delivering the best septic tank treatments for your septic tank system, we specialize in comprehensive services such as routine maintenance of clogged drains, septic tank pumping, and new system installations.

Blackstone Septic Service is a family-owned company with highly trained technicians, with over 75 years of experience in septic tanks, pipes and systems.